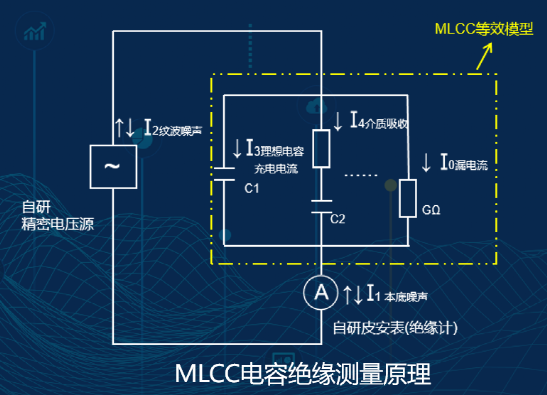

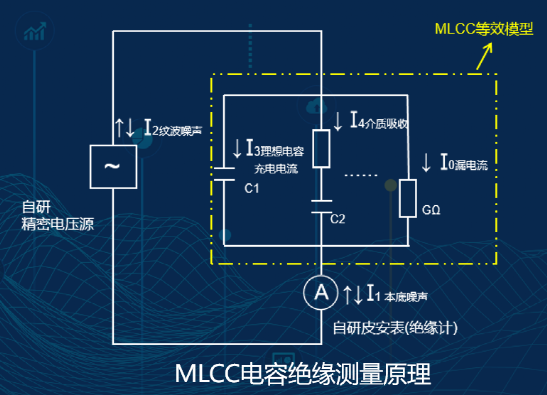

In the previous lesson of "Testing Technology Science Popularization Class", we learned that the measured current measured by the MLCC tester actually includes the five parts shown in the figure below: Imeasured current = I1 + I2 + I3 + I4 + I0

In this chapter, we will focus on analyzing the I2 component, the impact of different levels of power supply ripple on I2, thereby understanding the importance of the power supply, and how to evaluate the size of the power supply ripple to meet the needs of the MLCC tester.

Charge formula: △U * C = ripple current I2 * measurement time t

Ripple current I2 = △U * C/measurement time t

Industry standards for evaluating leakage current of different types of capacitors are as follows: The impact of different levels of power supply ripple on the I2 level:

Power supply ripple 1mV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 1mV*10uF/10mS = 1uA, from the table above, this ripple value is already comparable to the actual leakage current value. It can be seen that for MLCC testing, mV-level ripple is unacceptable.

100uV level ripple impact:

Power supply ripple 100 uV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 100uV*10uF/10mS = 0.1uA, from the table above, this ripple value has reached 10% of the standard leakage current value. It can be seen that for MLCC testing, this 100uV and above ripple level is also unacceptable.

50uV level ripple impact:

Power supply ripple 50 uV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 50uV*10uF/10mS = 0.05uA, from the table above, this ripple value has reached 5% of the standard leakage current value. It can be seen that for MLCC testing, this 50uV and above ripple level is also unacceptable.

10uV level ripple impact:

Power supply ripple 10 uV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 50uV*10uF/10mS = 0.01uA, from the table above, this ripple value has reached 1% of the standard leakage current value. It can be seen that for MLCC testing, the ripple current caused by the 10uV and below ripple level is acceptable.

The impact of different levels of power supply ripple on the I2 level:

Power supply ripple 1mV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 1mV*10uF/10mS = 1uA, from the table above, this ripple value is already comparable to the actual leakage current value. It can be seen that for MLCC testing, mV-level ripple is unacceptable.

100uV level ripple impact:

Power supply ripple 100 uV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 100uV*10uF/10mS = 0.1uA, from the table above, this ripple value has reached 10% of the standard leakage current value. It can be seen that for MLCC testing, this 100uV and above ripple level is also unacceptable.

50uV level ripple impact:

Power supply ripple 50 uV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 50uV*10uF/10mS = 0.05uA, from the table above, this ripple value has reached 5% of the standard leakage current value. It can be seen that for MLCC testing, this 50uV and above ripple level is also unacceptable.

10uV level ripple impact:

Power supply ripple 10 uV, capacitance 10uF, measurement time 10mS

Then: ripple current I2 = 50uV*10uF/10mS = 0.01uA, from the table above, this ripple value has reached 1% of the standard leakage current value. It can be seen that for MLCC testing, the ripple current caused by the 10uV and below ripple level is acceptable.

So, how to evaluate the ripple of the MLCC test system power supply?

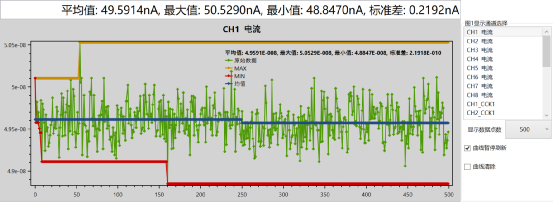

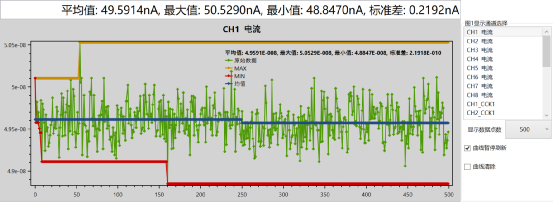

We recommend using a 200MΩ resistor in parallel with a 10uF MLCC to simulate the MLCC capacitor model for actual measurement. Below is a comparison of the test experiments of our self-developed instrument and the imported instrument SM7110: Figure: Self-developed power supply + self-developed instrument

Figure: Self-developed power supply + self-developed instrument

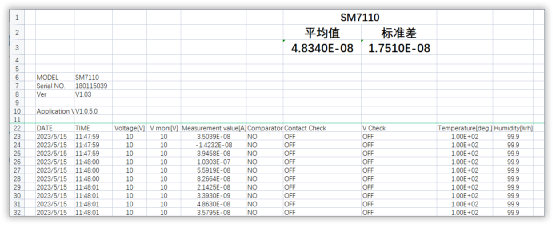

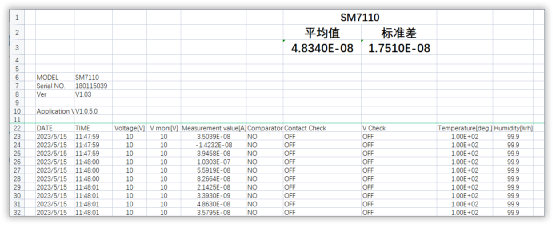

Figure: Imported Yokogawa: SM7110 high-resistance meter + automatic Yokogawa test software system

In the above two data diagrams, power supply equivalent noise evaluation:

Self-developed instrument: σI·t/C =0.2192nA*20ms/10uF ≈ 0.438uV

Imported 7110 Brand: σI·t/C =17nA*20ms/10uF ≈ 34uV

Therefore, although the 34uV ripple is considered relatively low, the impact of this level of ripple reaches 17nA, which is too high a proportion for the actual leakage current, seriously affecting the accuracy of high-speed measurement in production, and may lead to unreliable measurement data and misjudgment of measurement results.

Our instrument's power supply ripple is far less than 1uV, and the interference current caused is only 0.2192nA, which greatly reduces the interference caused by the power supply ripple of the power supply system and ensures the primary condition for accurate measurement—an ultra-low ripple precision voltage source.

Figure: Self-developed power supply + self-developed instrument

Figure: Self-developed power supply + self-developed instrument